How does Light Art Vision innovate?

With many years of design experience in hardware and firmware development of embedded systems, we innovate for world class organizations. We have a strong affinity for turning ideas into prototypes and cost effective, producible products. Our versatile skill base includes international standardization & compliance requirements for Industrial, Medical-, Apace & Aviation and Defense.

Our core competences are:

We love to work with Open Source Software

And we mainly use:

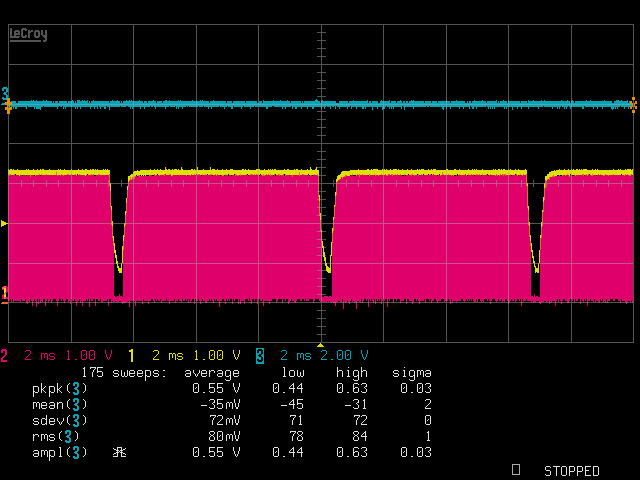

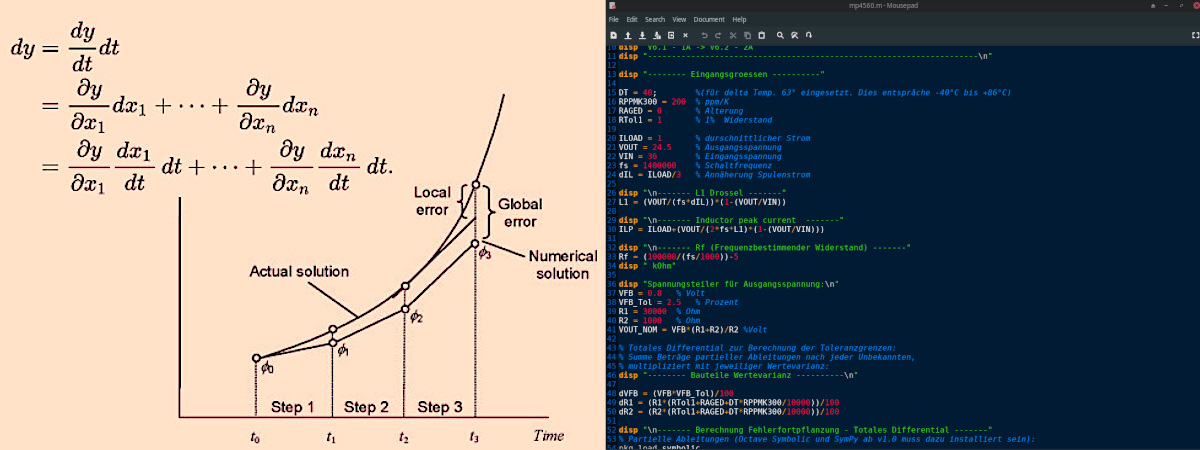

Feasibility studies, tolerance calculations, thermal modeling & simulations, validation and reliability documentation are our daily tasks.

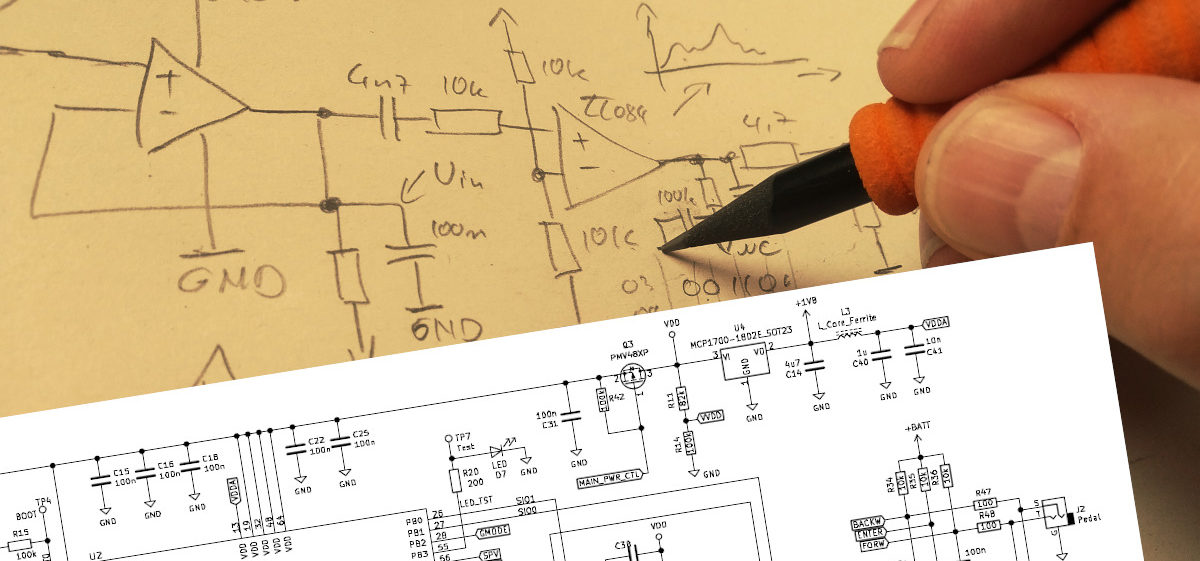

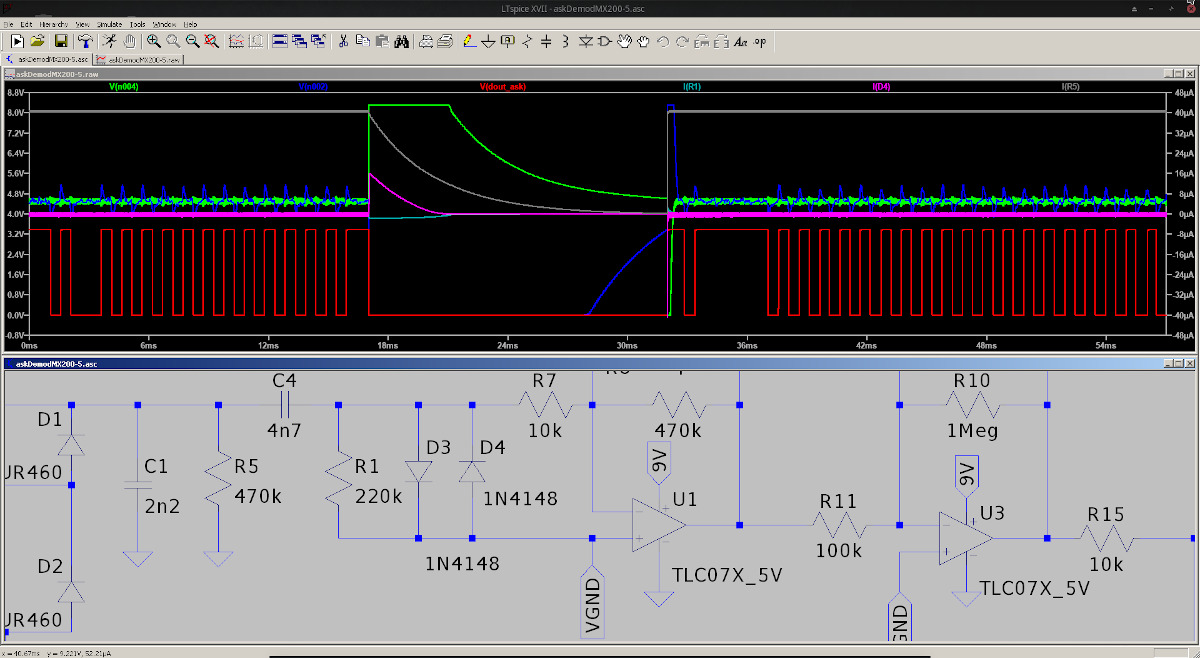

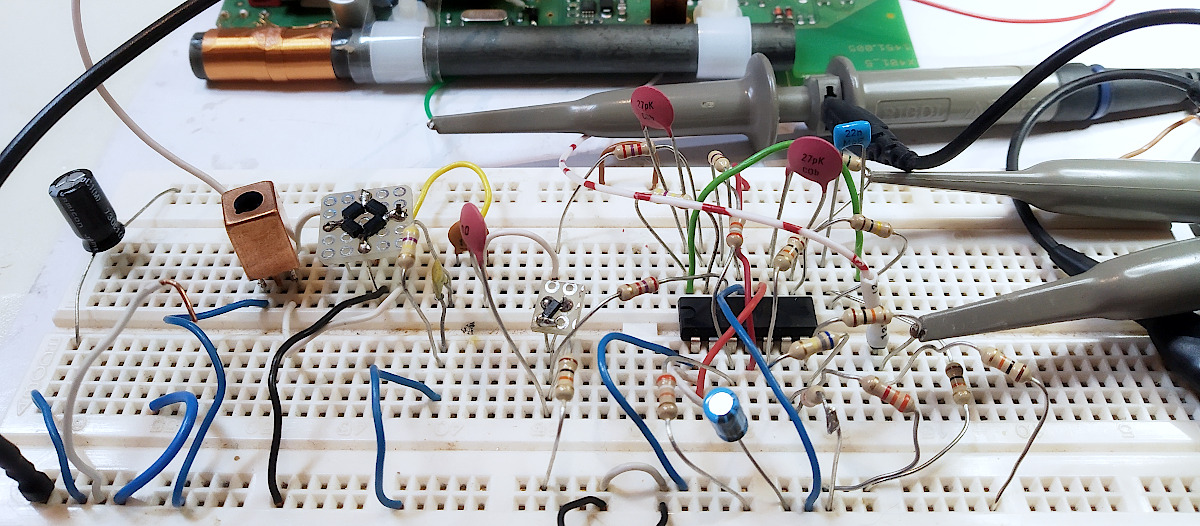

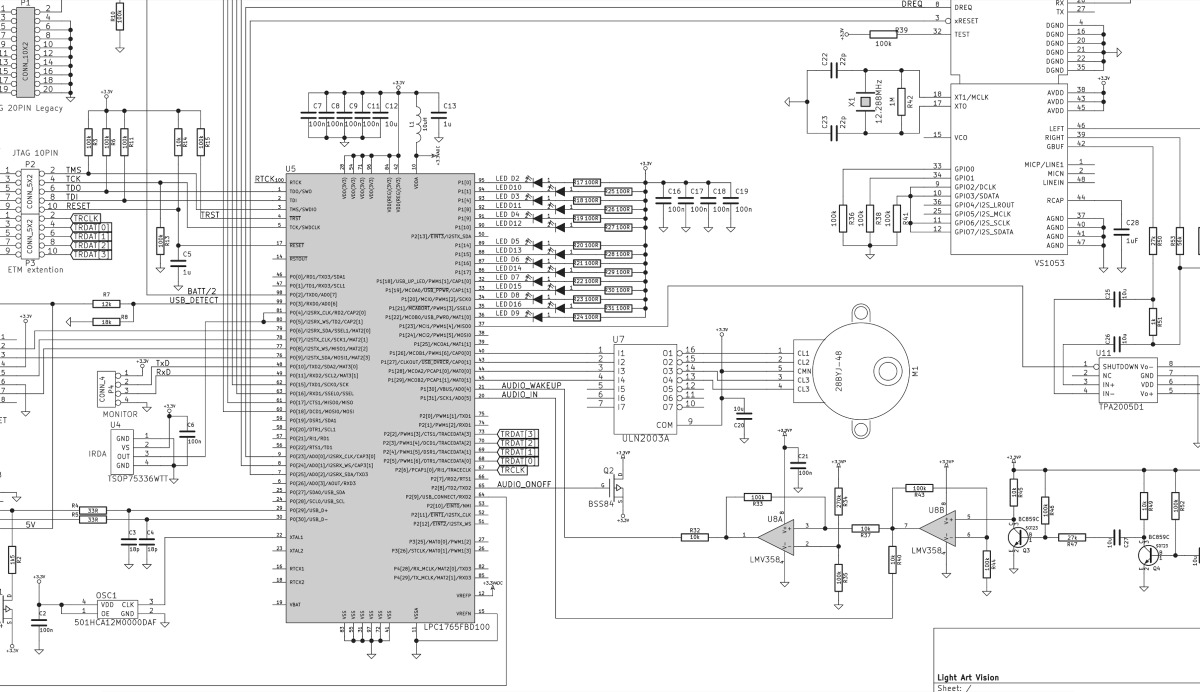

Analog Circuit Design

Resistors, capacitors, inductors, bipolar junction transistors, MOSFETs, operational amplifiers and comparators are the most common components in analog circuits. Before we evaluate specific Integrated Circuits for new designs, we always evaluate, if simple, low expensive common discrete components would fill the purpose. Therefore, availability is maximized and costs minimized in most cases. |

Let us know about your ideas, projects and requirements!

We are more than happy to share our knowledge, support, develop, build, train, teach and consult.

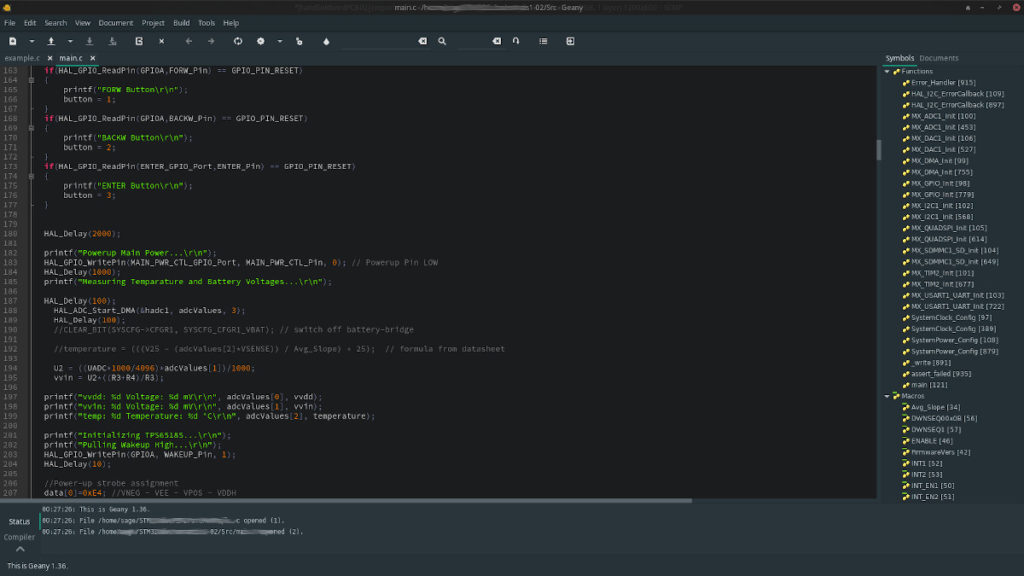

If an embedded System is part of the design (which in most cases is), many tests can be done with an evaluation board of the desired Microcontroller. PWMs, ADCs, Interrupts, Capture Compare, DACs or just GPIOs can be evaluated and basic functionality confirmed. Most Eva-Boards have a programmer on board.

If an embedded System is part of the design (which in most cases is), many tests can be done with an evaluation board of the desired Microcontroller. PWMs, ADCs, Interrupts, Capture Compare, DACs or just GPIOs can be evaluated and basic functionality confirmed. Most Eva-Boards have a programmer on board.

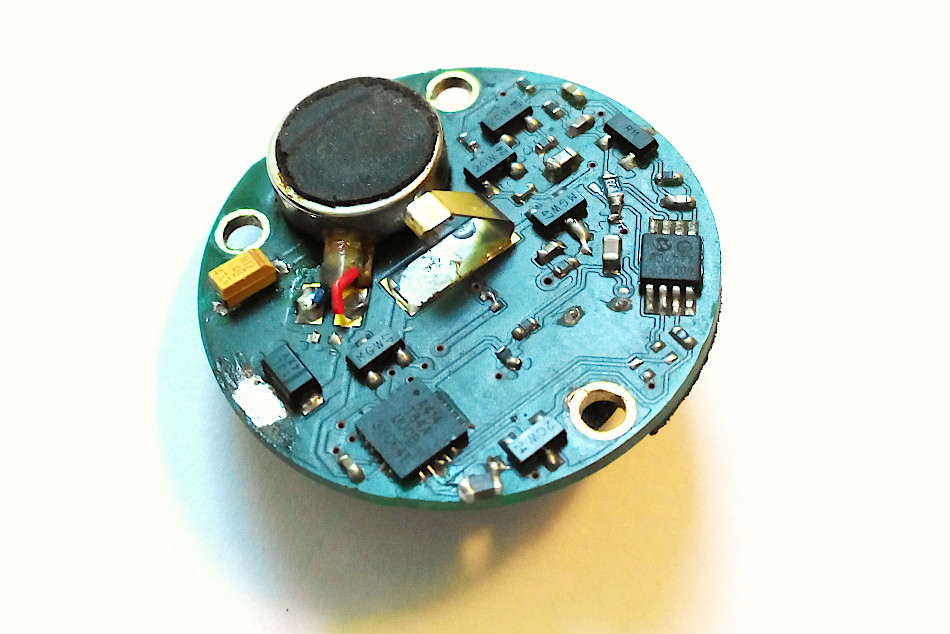

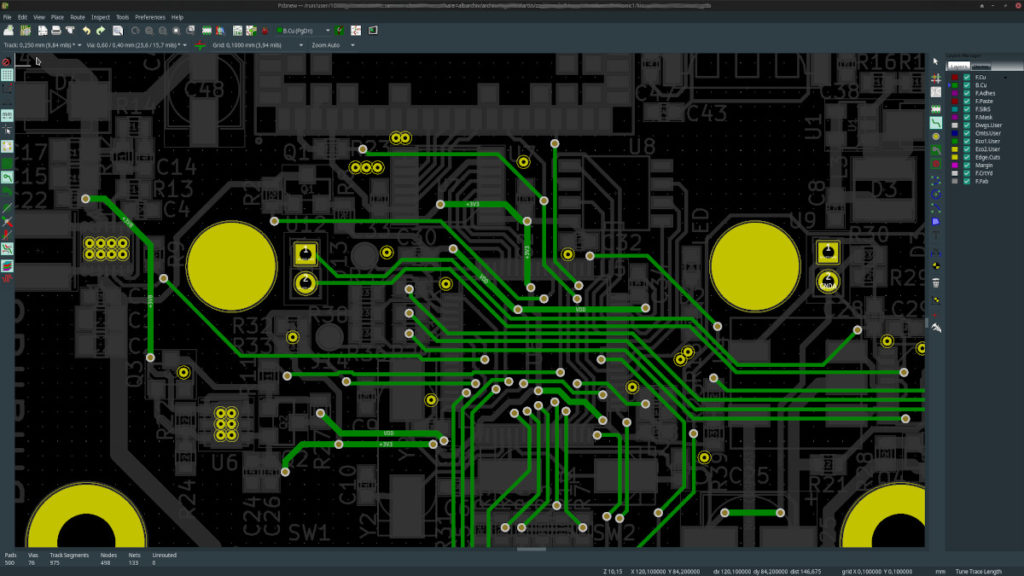

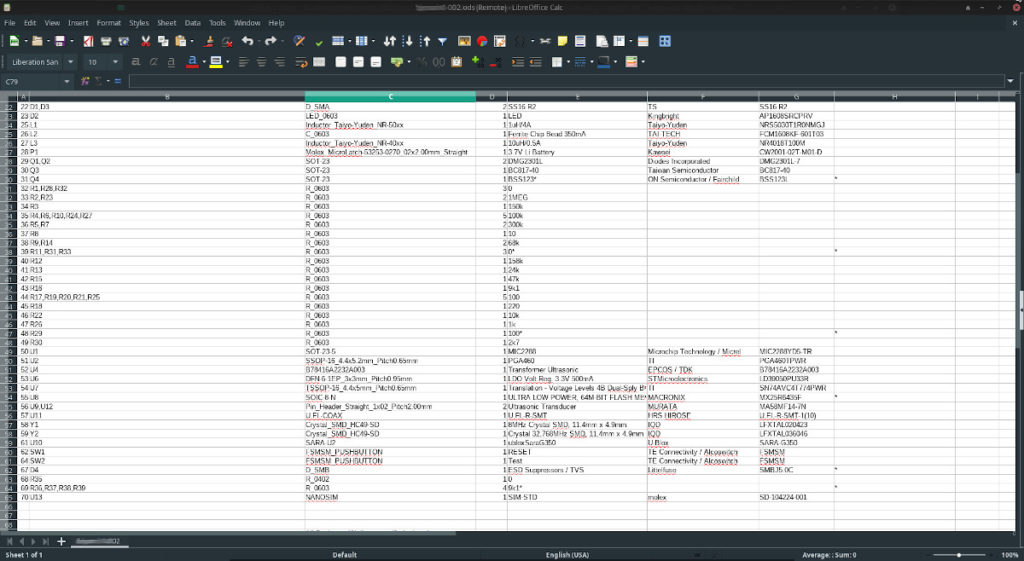

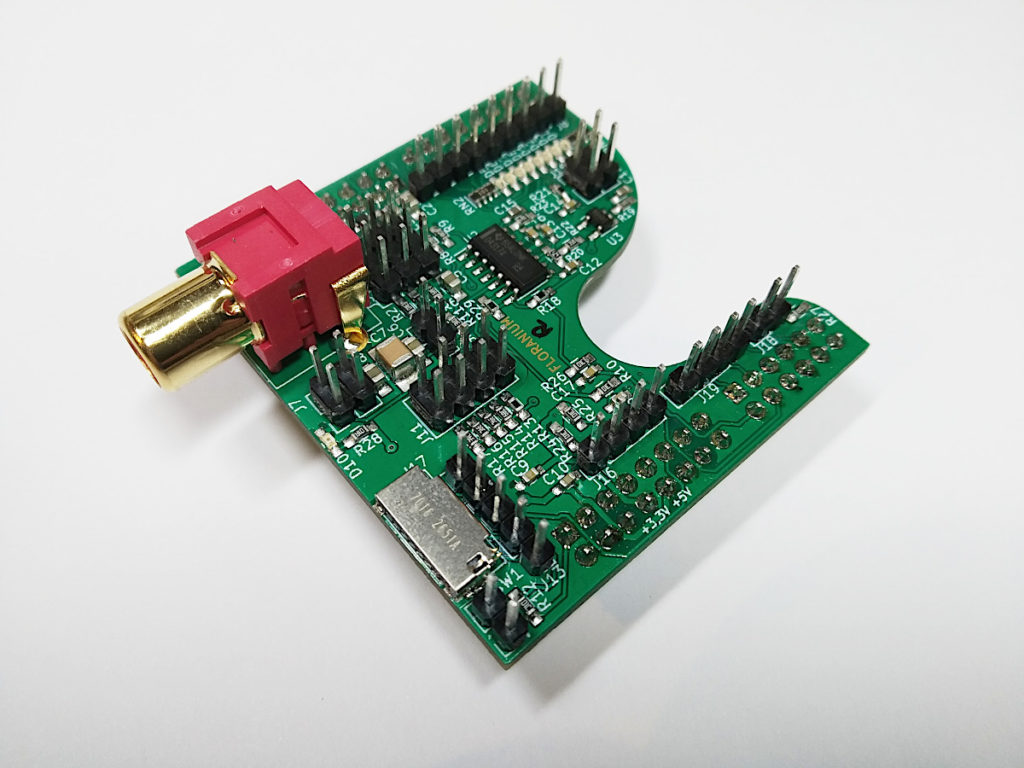

e PCB Board is most likely the next step in the design process. Good Layouts meet all the power requirements while optimized for EMC (Electromagnetic Compatibility) and Signal Integrity. We have many years of such board design experience.

e PCB Board is most likely the next step in the design process. Good Layouts meet all the power requirements while optimized for EMC (Electromagnetic Compatibility) and Signal Integrity. We have many years of such board design experience.

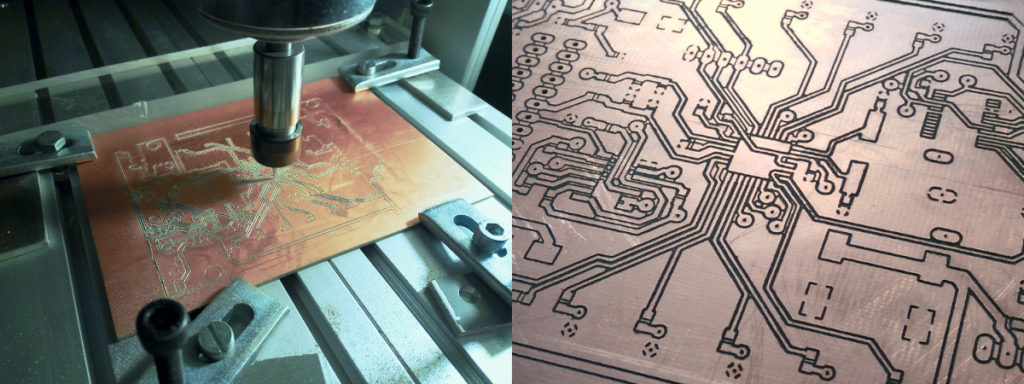

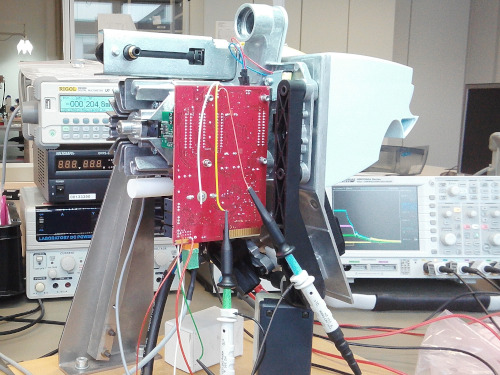

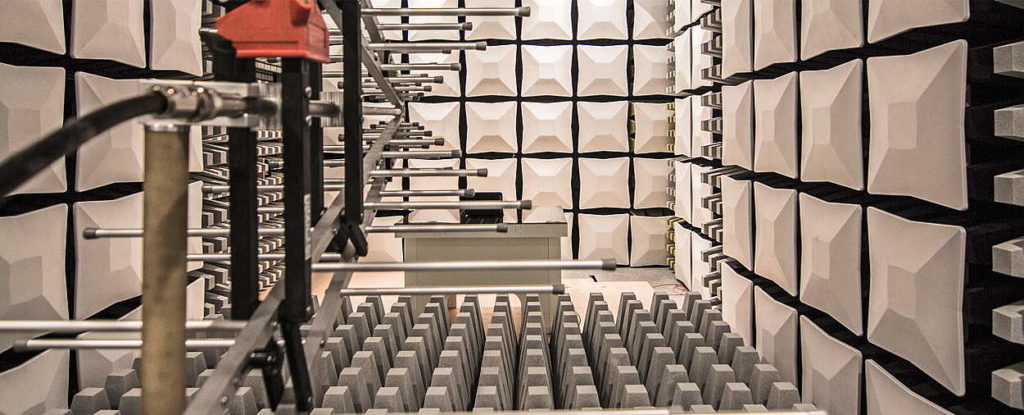

When all test results are nominal, a second prototyping phase can be started with more than just one PCB for field tests. EMC tests and certifications will be performed at this time. Clear documentation of all test results are a must. If a product fails some time later when in use, possible causes can be found in this documentation.

When all test results are nominal, a second prototyping phase can be started with more than just one PCB for field tests. EMC tests and certifications will be performed at this time. Clear documentation of all test results are a must. If a product fails some time later when in use, possible causes can be found in this documentation.